How Caster Wheel Materials Impact Durability in Retail Environments

Understanding Caster Wheel Material and Its Impact on Longevity

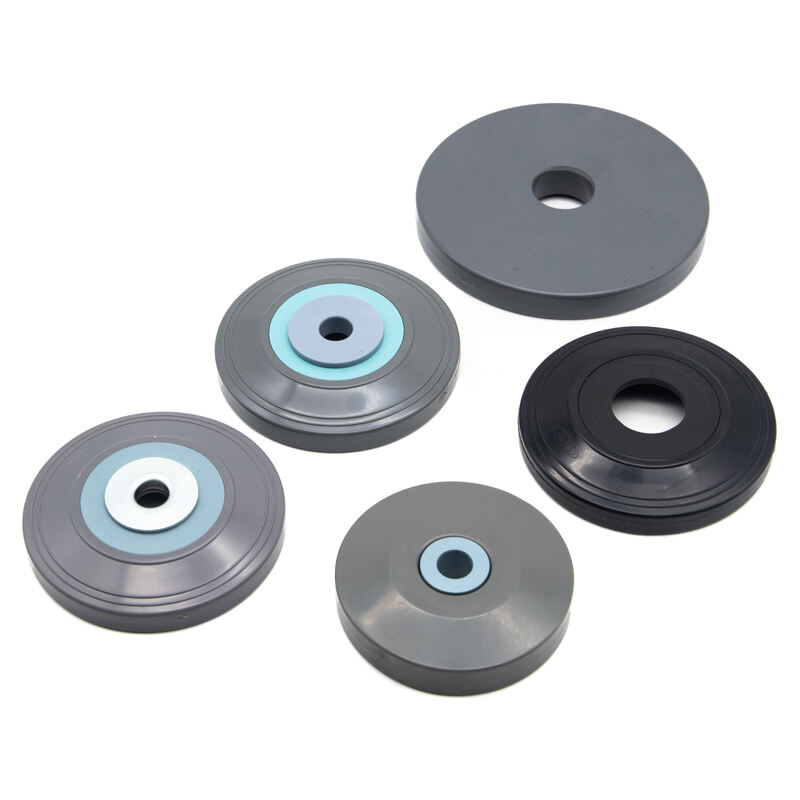

What kind of materials go into shopping cart wheels makes all the difference when it comes to lasting through the constant wear and tear of busy stores. Take polyurethane wheels for example they tend to hold up about 2 or 3 times better than regular rubber ones in places where lots of people walk around. This happens because polyurethane is just denser and doesn't wear down as fast. According to some recent studies on materials, this matters a lot. Stores that invest in wheels capable of handling at least 800 pounds of moving weight see their replacement costs drop by roughly 40% each year. Cheaper alternatives simply can't stand up to the stress of carts being pushed around with different weights in them throughout the day.

Comparing Rubber, Polyurethane, Nylon, and Metal Wheels for Durability

| Material | Key Durability Traits | Optimal Use Cases |

|---|---|---|

| Rubber | Shock-absorbent; prone to tread separation | Light-duty carts on smooth surfaces |

| Polyurethane | Resists cuts/scuffs; handles lateral forces | High-capacity carts; uneven floors |

| Nylon | Impervious to chemicals; brittle in cold temps | Refrigerated sections |

| Metal | Unmatched load capacity; damages tile/vinyl | Industrial stock carts |

Polyurethane stands out for balancing floor protection and durability, while metal offers maximum strength at the cost of surface safety. Nylon excels in chemical resistance but becomes fragile in cold storage areas, and rubber, though quiet, wears prematurely under heavy or shifting loads.

How Tread Material Selection Affects Resistance to Wear and Cracking

The makeup of the tread actually determines around 70 to 75% of how long a wheel will last in grocery store settings according to recent maintenance data from 2023 fleets. When it comes to materials, dual density polyurethane has become pretty popular lately because it combines a softer outer surface with a harder inner core. This design cuts down on tread peeling problems by roughly half compared to regular solid rubber options. Now regarding hardness levels measured on that Shore A scale most people talk about, there's definitely a sweet spot depending on what kind of floors we're dealing with. Wheels rated between 85A and 90A work really well on concrete surfaces where durability matters most. But if stores have those shiny retail floors that need protecting, going with something softer like 70A to 75A makes sense too since these won't leave marks while still providing good grip when needed.

Performance of Caster Wheels Under Shifting or Unbalanced Loads

When moving heavy stuff around, sudden weight shifts tend to crack hubs on plastic or cheap nylon wheels all too frequently. Stores that switched from regular carts to ones with glass fronts saw their wheel problems drop by about 31% once they upgraded to forged steel stems combined with polyurethane treads. These materials just handle the pressure better across different surfaces. And let's not forget about those wheels with tapered roller bearings either. They cut down on wobble wear by roughly 19% compared to standard setups, making them much safer for rolling through tight spaces where customers might be walking nearby.

Safety Implications of Caster Wheel Selection in Shopping Carts

Common Safety Concerns and Failure Points in Shopping Cart Caster Wheels

Common problems with bad caster choices include wheel jams, uneven tire wear, and wobbling when making tight corners. Small or cheap plastic wheels just don't spread weight properly across the cart, which makes them tip over easily, particularly if someone stacks stuff unevenly inside. According to a recent look at retail safety data from last year, nearly a third of all shopping cart accidents happened because wheels suddenly locked up on smooth surfaces or got caught in floor debris. Most often, these breakdowns happen with materials that aren't built to last long term. We see this a lot with inferior nylon components or flimsy rubber tires that start cracking after only a few months of constant rolling back and forth.

How Proper Caster Wheel Materials Enhance Stability and Reduce Accidents

Materials like thermoplastic rubber (TPR) and reinforced polyurethane really make a difference when it comes to keeping things stable. They provide better grip and spread weight more evenly across surfaces. The TPR wheels actually absorb about half again as much shock compared to regular plastic casters, which means carts don't tend to wobble around so much during movement. A company called Caster Concepts did some testing and found that their designs featuring those fancy precision bearings cut down on the effort needed to steer by roughly 30 percent. This matters because sudden direction changes are what cause most of those annoying collisions we see happening all the time in crowded retail environments.

Low-Cost Plastic Casters vs. Long-Term Safety: Risks and Industry Concerns

Budget plastic casters might save money upfront but come with hidden problems down the road. They usually handle around 80 to 120 pounds each, which isn't enough for heavy duty work, plus they break down when exposed to sunlight over time. Supermarkets have seen this firsthand - stores report needing to replace these cheap wheels about three times as often as the better quality polyurethane ones. That adds up fast too, costing roughly $2,100 extra every year just for maintaining 100 shopping carts. After a real mess happened in 2022 when some plastic casters snapped during busy hours causing multiple carts to crash into each other in one of the main aisles, regulatory bodies are finally getting serious about setting proper standards for how durable these parts need to be.

Matching Caster Wheel Size and Load Capacity to Cart Usage

Balancing Wheel Size and Load Capacity for Optimal Performance

The right wheel size directly influences cart stability and weight handling. Larger diameters (6+ inches) support heavier loads (500+ lbs) and roll more easily over thresholds and uneven surfaces, while smaller wheels (2–4 inches) suit lightweight applications but risk failure under excess weight.

| Wheel Diameter | Load Capacity Range | Common Retail Applications |

|---|---|---|

| 2-4 inches | Up to 150 lbs | Hand baskets, promotional displays |

| 4-6 inches | 150-500 lbs | Standard shopping carts, stock carts |

| 6+ inches | 500-1,000+ lbs | Bulk-item carts, inventory pallets |

As outlined in recent industry guidelines, matching diameter to load reduces bearing stress by 32% compared to mismatched setups. Surface compatibility remains key: hard nylon works well on smooth floors, while softer polyurethane protects delicate flooring in high-traffic zones.

Preventing Overloading Failures With High-Quality Caster Wheels

Shopping carts tend to break down quite a bit because of overloaded casters, according to some industry reports from 2024 that put this problem at around 41%. Most of these failures happen when stores don't properly account for all those forces acting on the wheels during quick stops or sharp turns. What do the experts say? They suggest figuring out the actual weight of each cart including whatever goods might be inside, then throwing in an extra 25 to 30 percent just to be safe when picking out wheels. Take a standard cart holding about 600 pounds for instance – good practice would be to install casters rated for at least 750 pounds altogether. The better quality options featuring steel cores and those fancy dual row ball bearings really stand out here. These premium wheels can stick around three times longer than cheaper plastic ones that just crack apart whenever there's any kind of imbalance in how weight gets distributed across them. And remember folks, always check if those load numbers on packaging actually cover both situations where the cart isn't moving and when it is zipping around the store.

Innovations in Application-Specific Caster Design for Supermarkets

How Tailored Caster Design Improves Functionality and Safety in Retail

Supermarkets today rely on caster wheels built specifically for their daily operations. The newer designs come with wheel sizes ranging between four to six inches, plus swivel mechanisms that make it easier to navigate crowded aisles and stock shelves without tipping over on those shiny floor surfaces. Some manufacturers have developed special rubber treads that cut down sideways movement by around forty percent when tested against regular casters back in 2023. This matters a lot because grocery stores see so many customers walking through every day, especially near the fresh produce section where spills happen regularly.

Trend Analysis: Adoption of Hybrid Materials Like TPR and PU in Modern Carts

Manufacturers are increasingly combining thermoplastic rubber (TPR) with polyurethane (PU) to balance performance, noise control, and cost:

| Material Combination | Durability Improvement | Noise Reduction | Cost Premium |

|---|---|---|---|

| TPR Core + PU Surface | 2.3x vs. pure PVC | 58% quieter | 15–20% |

| Steel Hub + PU Roller | 3.1x load capacity | Vibration-free | 25–30% |

This hybrid approach tackles two major retail concerns: noise disruption—cited in 85% of 2024 customer feedback surveys—and recurring wheel failures that strain maintenance teams. By integrating material strengths strategically, retailers achieve longer service life and improved shopper experience without compromising on safety or efficiency.

FAQ About Caster Wheels in Retail Environments

What are the best materials for caster wheels in retail environments?

Polyurethane is a popular choice due to its durability and resistance to wear. Nylon offers chemical resistance, while thermoplastic rubber and reinforced polyurethane provide stability and shock absorption.

How do wheel diameters affect performance in retail settings?

Larger diameters (6+ inches) support heavier loads and navigate uneven surfaces better, while smaller wheels (2–4 inches) are suited for lighter applications.

Why are hybrid materials gaining popularity in caster wheel design?

Hybrid materials like thermoplastic rubber combined with polyurethane balance performance, durability, noise control, and cost-effectiveness, addressing major retail concerns.

What are common issues with low-cost plastic casters?

They have limited load capacity and are susceptible to damage from sun exposure and heavy use, requiring more frequent replacements.